ISITSIMBI SOMSEBENZI Oshisayo

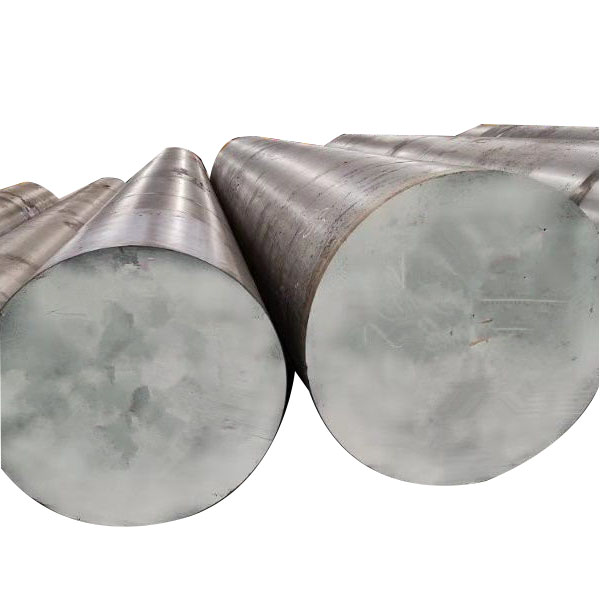

Hot Umsebenzi Ithuluzi Steel kokuzihlanganisa Round bar

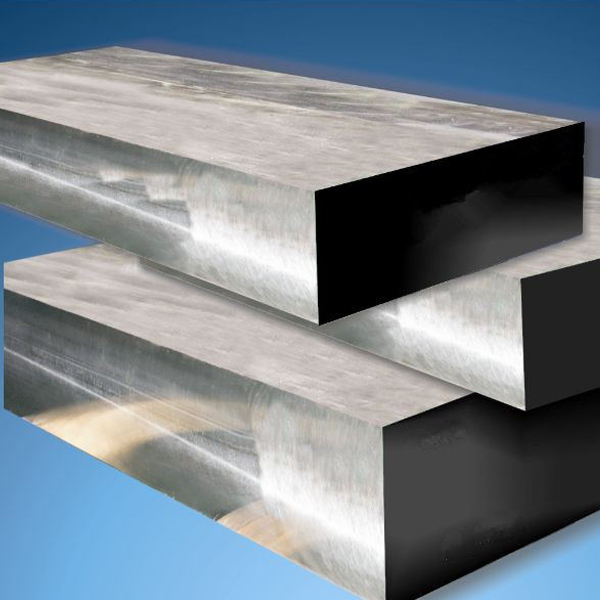

Ithuluzi Elisebenzayo Lensimbi Eligoqiwe Ibha Flat

Ithuluzi Lokusebenza Elishisayo Lensimbi Engenalutho

Ithuluzi Lokusebenza Elishisayo Lensimbi Eligoqwe Lafa

Ukusebenza komkhiqizo

Hot Work Ithuluzi Steel babe izakhiwo ezilandelayo:

Ukumelana nokushisa

Ukumelana nokushaqeka okushisayo

Amandla aphezulu okushisa

Ubulukhuni bokushisa okuphezulu

Izinga lokushisa eliphezulu lokushisa

Ukumelana nokushisa okuphezulu okushisa okuphezulu

Ukusebenza komkhiqizo

I-Hot Work Tool Steel, njengoba igama labo lisho, isetshenziswa lapho ukusebenza kwamazinga okushisa kwethuluzi kungafinyelela emazingeni lapho ukumelana nokuthamba, ukuhlola ukushisa nokwethuka kubalulekile, Inokumelana nokushisa okuphezulu nokumelana kokugqoka okuphakathi, ukuphazamiseka kokuqina kuhamba kancane.

Leli qembu lensimbi lihle kakhulu ekusetshenzisweni okunjenge-die-casting dies, i-extrusion dies, i-plastic molding Dies, i-Hot forging Dies, i-Hot gripper ne-Dies ehamba phambili, ama-mandrel ashisayo, ama-punches womsebenzi oshisayo nemimese eshisayo ye-shear

Ikakhulu Umsebenzi Wokushisa Wensimbi Ibanga Cha. Sihlinzekiwe:

| UMLANDO |

I-GB (CHINA) |

IDINI |

I-ASTM |

I-JIS |

| I-HSH 13 | 4Cr5MoSiV1 | 1.2344 | H13 | SKD61 |

| I-HSH11 | 4Cr5MoSiV | 1.2343 | H11 | I-SKD6 |

| HSH12 | 4Cr5MoWSiV | 1.2606 | H12 | SKD62 |

| HSH10 | 4Cr3Mo3SiV | 1.2365 | H10 | I-SKD7 |

| HSH21 | 3Cr2W8V | 1.2581 | H21 | I-SKD5 |

| HSH6 | 5CrNiMo | 1.2714 | L6 |

UKWAKHIWA KWAMAKHEMIKHALI

|

UMLANDO |

IDINI |

I-ASTM |

UKWAKHIWA KWAMAKHEMIKHALI |

IMPAHLA |

ISICELO |

||||||||

|

C |

Si |

Mnu |

P≤ |

S≤ |

Cr |

Mo |

V |

UW |

|||||

|

HSH13 |

1.2344 |

H13 |

0.35-0.42 |

0.80-1.20 |

0.25-0.50 |

0.030 |

0.030 |

4.80-5.50 |

1.20-1.50 |

0.85-1.15 |

- |

Ukuqina okuphezulu, ukumelana nokugqoka okuhle kakhulu nokuqina okushisayo. inokumelana okuhle kokushisa okushisayo, (i-ESR) i-H13 ine-homogeneity enkulu kanye nesakhiwo esihle kakhulu, okuholela ekusebenzeni okuthuthukile, ukupholisha kanye namandla okushisa aphezulu. |

Ingcindezi die casting amathuluzi, extrusion die, forging dies, blade hot shear, stamping dies, plastic molds, Hot work mandrels, ESR H13 is great for aluminium die-casting tools and plastic mold mold tools require a very high polish. |

|

HSH12 |

1.2606 |

H12 |

0.32-0.40 |

0.90-1.20 |

0.30-0.60 |

0.030 |

0.030 |

5.00-5.60 |

1.30-1.60 |

0.15-0.40 |

1.20-1.40 |

Ukuqina komthelela omuhle kakhulu. Okuqukethwe kwe-tungsten kunikeza ukumelana nentukuthelo okungcono, ukuqina okujulile, insimbi eqinisa umoya ekhombisa ushintsho lwesayizi omncane ngesikhathi sokwelashwa kokushisa. Ukumelana okuhle nokuqhekeka kokukhathala okushisayo |

izibhakela ezishisayo, kufa ukusakaza kufa, ukwakha okokufa, ukushisa kwe-shear hot, ukushisa okushisayo kuyafa, nokufa kwe-extrusion. |

|

YTR50 |

1.2343 |

H11 |

0.33-0.41 |

0.80-1.20 |

0.25-0.50 |

0.030 |

0.030 |

4.80-5.50 |

1.10-1.50 |

0.30-0.50 |

- |

Ukuqina okuphezulu, ubunzima obuhle kakhulu, ukumelana okuhle nokushaqeka okushisayo lapho amanzi esepholile enkonzweni, ushintsho lwesayizi oluncane ngesikhathi sokwelashwa kokushisa. |

Inconyelwe izinhlelo zokusebenza ezishisayo zamathuluzi lapho kudingeka khona ukumelana okuphezulu nokuqhekeka. Izibhakela ezishisayo, kufa ukusakaza kufa, ukwakha okokufa, ukushisa okushushu kwe-shear, ukushisa okushisayo kuyafa, ukufa kwe-extrusion. |

|

HSH10 |

1.2365 |

H10 |

0.28-0.35 |

0.10-0.40 |

0.15-0.45 |

0.030 |

0.030 |

2.70-3.20 |

2.50-3.00 |

0.40-70 |

- |

Ukumelana okuhle kakhulu ekuthambiseni ekushiseni okuphezulu. ukumelana kakhulu nokuqhekeka kokukhathala okushisayo, futhi kungenziwa amanzi apholile enkonzweni |

Heavy metal Die-ekubunjweni amathuluzi, Ukubhoboza Mandrels, punches Zezıhlabane, ekwakheni uyafa, hot phuca izindwani |

|

HSH21 |

1.2581 |

H21 |

0.25-0.35 |

0.10-0.40 |

0.15-0.45 |

0.030 |

0.030 |

2.50-3.20 |

- |

0.30-0.50 |

8.50-9.50 |

Ibonisa ukumelana okuhle kakhulu ekuthambiseni ekushiseni okuphezulu. Akufanele kupholiswe amanzi enkonzweni ngaphandle kokuthi ithuluzi lifaka ukugeleza okuqhubekayo kokupholisa kwamanzi kwangaphakathi. Ukushaqeka okushisayo kufanele kugwenywe |

Kunconywe ukusebenza okushisayo kwezinsimbi zokusebenza njenge-bronze extrusion, ithusi lokufa, izigaxa ezishisayo, ukufaka okokufaka okufayo. |

|

HSH6 |

1.2714 |

L6 |

0.50-0.60 |

0.10-0.40 |

0.60-0.90 |

0.030 |

0.030 |

0.80-1.20 |

0.35-0.55 |

0.05-0.15 |

Ni 1.50-1.80 |

Ukuqina komthelela omkhulu nokumelana okuhle nokuthambisa emazingeni okushisa aphakeme. ukumelana okuhle nokwethuka okushisayo nokuqhekeka kokukhathala okushisayo, izinguquko ezincane ezenziwa ngesikhathi sokuqina. |

Die ekwakheni, afe ekubunjweni, extrusion, ingilazi ukucutshungulwa,. AmaMandrels, abaphathi beDie |

Ikakhulukazi Cold Umsebenzi Ithuluzi Steel Ibanga No. thina enikeziwe:

|

UMKHIQIZO |

ISIKHATHI SOKULETHA NOKUTHOLA OKUTHOLAKALAYO |

|||

|

IBHAYIBHILI ELIZUNGILE |

UKUDWALWA OKUBANDA |

UMHLABA ONGAPHAKATHI |

PEELED |

KUPHENDUKILE |

|

IDAYILI KU-MM |

2.5-12.0 |

8.5-16 |

16-75 |

75-610 |

|

ISIKWELEKI |

OKUSHESHWE Sigoqwe Mnyama |

KHOHLWA LONKE UHLANGOTHI LUTHUTHULIWE |

||

|

SIZE IN MM |

6X6-50X50 |

55X55-510X510 |

||

|

IFLETHI IBHALE |

OKUSHESHWE Sigoqwe Mnyama |

KHOHLWA LONKE UHLANGOTHI LUTHUTHULIWE |

||

|

UBubanzi obungu-X NGOMNYAKA |

3-40 X 12-610 |

80-405 X 100-810 |

||

|

IDISKI |

I-350-800MM DIA X80-400 ETHILE |

|||